Cathodic Protection Materials: Safeguarding Metal Structures from Corrosion

Introduction

Corrosion is a persistent threat to metal structures, causing deterioration, weakened integrity, and significant maintenance costs. Cathodic protection is a proven method to combat corrosion effectively. It involves the use of specific materials to create a controlled electrochemical process that prevents the corrosion of metal surfaces. In this article, we will explore cathodic protection materials, their types, functions, benefits, and applications across various industries.

- Understanding Cathodic Protection Materials

Cathodic protection materials are essential components used to establish cathodic protection systems. These materials are strategically selected to create an environment that shifts the electrochemical potential of the metal structure to a less corrosive state, effectively inhibiting corrosion.

- Types of Cathodic Protection Materials

2.1 Sacrificial Anodes

Sacrificial anodes are made of metals that are more electrically active than the protected metal structure. Common materials used for sacrificial anodes include zinc, aluminum, and magnesium. These anodes corrode sacrificially, diverting the corrosion process away from the protected structure.

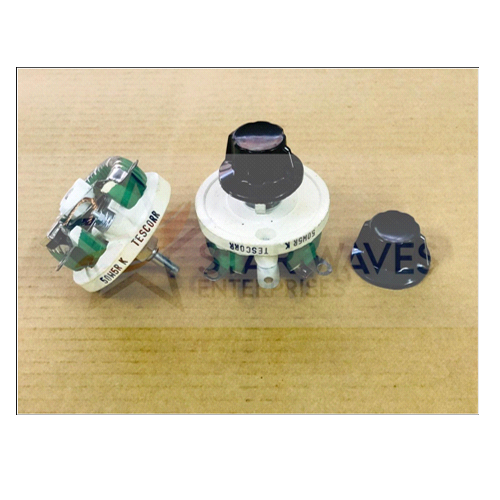

2.2 Impressed Current Anodes

Impressed current anodes, also known as inert anodes, are made from materials like platinum, graphite, or mixed metal oxides. They are connected to an external power source that supplies a controlled electrical current to the metal structure, counteracting the natural corrosion process.

- Functions and Benefits of Cathodic Protection Materials

3.1 Corrosion Prevention

Cathodic protection materials actively prevent corrosion by altering the electrochemical potential of the metal surface, making it less susceptible to oxidation.

3.2 Extended Service Life

By effectively mitigating corrosion, cathodic protection materials significantly extend the service life of metal structures, reducing maintenance and replacement costs.

3.3 Minimal Environmental Impact

Cathodic protection is an environmentally friendly method of corrosion prevention, as it reduces the need for chemical inhibitors and coatings.

- Applications of Cathodic Protection Materials

4.1 Underground Pipelines

Cathodic protection materials are widely used to protect buried pipelines used in oil, gas, and water distribution systems.

4.2 Marine Structures

In maritime environments, cathodic protection materials safeguard ships, docks, piers, and other submerged or water-exposed structures.

4.3 Storage Tanks

Above-ground and underground storage tanks, used for various liquids including fuels and chemicals, benefit from cathodic protection to prevent corrosion and leaks.

- Considerations for Choosing Cathodic Protection Materials

5.1 Environmental Factors

Select cathodic protection materials that are suitable for the specific environmental conditions of the application, such as soil composition or water salinity.

5.2 Electrode Longevity

Evaluate the expected lifespan of sacrificial anodes or impressed current electrodes to ensure effective and cost-efficient corrosion prevention.

5.3 Maintenance Requirements

Different cathodic protection materials may have varying maintenance needs, so consider the ease of inspection and replacement when making choices.