Anode Junction Box: Enhancing Corrosion Protection in Industrial Applications

Introduction

In industrial settings, corrosion poses a significant threat to the longevity and efficiency of critical structures and equipment. To combat this issue, engineers and industries often employ various cathodic protection methods. One such method is the use of anode junction boxes. In this article, we will explore the importance of anode junction boxes, their functions, benefits and their role in enhancing corrosion protection in industrial applications.

Understanding Corrosion and Cathodic Protection

Before delving into anode junction boxes, it’s essential to grasp the concept of corrosion and how cathodic protection works. Corrosion is a natural electrochemical process that causes metal structures to deteriorate when exposed to environmental factors such as moisture, salts and chemicals. Cathodic protection is a technique used to prevent this deterioration by making the metal structure the cathode of an electrochemical cell.

What is an Anode Junction Box?

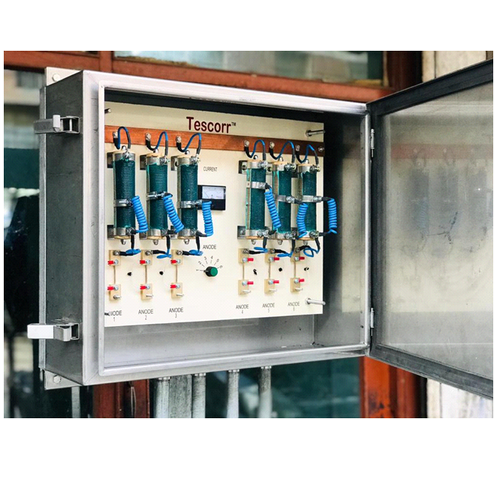

An anode junction box is a critical component of a cathodic protection system. It serves as a central point where multiple anodes are connected to provide a distributed flow of protective current to the structure being protected. Anode junction boxes are designed to ensure uniform current distribution, maximizing the effectiveness of the cathodic protection system.

The Function of Anode Junction Boxes

Anode junction boxes play a pivotal role in the efficient functioning of cathodic protection systems. Their primary functions include:

- Anode Connection

Anode junction boxes provide a secure and efficient connection for multiple anodes. The anodes are often buried in the ground or submerged in water and the junction box protects the connections from environmental elements, ensuring continuous current supply.

- Current Distribution

Anode junction boxes ensure uniform distribution of electrical current to the connected anodes. This even distribution prevents localized corrosion and ensures comprehensive protection for the entire structure.

- Monitoring and Control

Advanced anode junction boxes come equipped with monitoring and control systems. These systems allow engineers to measure the effectiveness of the cathodic protection and make adjustments as needed, ensuring optimal performance at all times.

Benefits of Anode Junction Boxes

Using anode junction boxes in cathodic protection systems offers several significant benefits:

- Enhanced Corrosion Protection

The precise and uniform distribution of protective current by the anode junction boxes significantly enhances the corrosion protection of metal structures, prolonging their service life.

- Cost-Efficiency

Anode junction boxes streamline the cathodic protection process, reducing maintenance costs and minimizing the need for frequent inspections and repairs.

- Increased System Longevity

With efficient protection, the overall longevity of industrial structures and equipment is improved, reducing replacement and downtime costs.

- Environmental Friendliness

Cathodic protection systems, with the aid of anode junction boxes, help prevent premature disposal of metal assets, reducing the environmental impact of corrosion.

Choosing the Right Anode Junction Box

Selecting the appropriate anode junction box is crucial for the effectiveness of the cathodic protection system. When choosing, consider the following factors:

- Material Quality

Opt for anode junction boxes made from durable and corrosion-resistant materials to ensure their longevity and reliability in harsh environments.

- Current Carrying Capacity

Ensure that the junction box can handle the required current capacity, considering both present and future needs.

- Environmental Protection

Look for junction boxes with adequate environmental protection, such as IP ratings to safeguard the electrical connections from moisture, dust and chemicals.