Introduction

In three-phase power systems, efficient control of electrical devices is crucial for optimal performance. Silicon-Controlled Rectifier (SCR) controllers play a vital role in regulating power to various equipment and machinery. This article delves into the world of SCR controllers, explaining their functionality, benefits, and applications.

What is an SCR Controller?

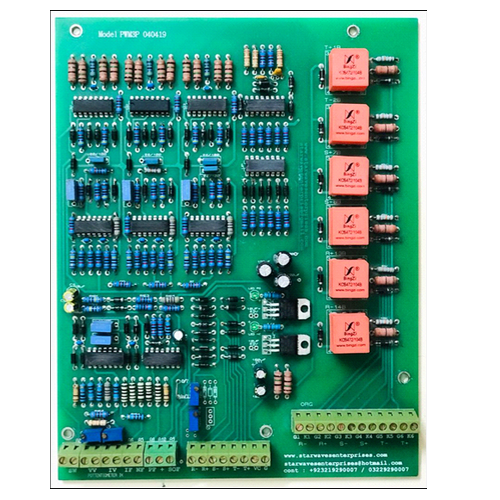

An SCR controller, also known as a thyristor power controller, is a semiconductor device widely used to manage power flow in three-phase systems. It is a solid-state switching device that controls the flow of alternating current (AC) to loads like electric heaters, motors, and other industrial machinery. SCR controllers offer precise and rapid power modulation, making them suitable for various industrial and commercial applications.

How does an SCR Controller Work?

An SCR controller operates by using a small voltage, known as the gate signal, to control a much larger voltage across the main terminals. When the gate signal is applied, the SCR allows the current to flow continuously, like a closed switch. Conversely, when the gate signal is removed, the SCR turns off, interrupting the current flow. This on-off mechanism enables the SCR controller to regulate the power supplied to the connected load.

Advantages of SCR Controllers

- Efficiency

- Precise Control

- Durability and Reliability

- Low Maintenance

- Industrial Heating Systems

- Motor Control

- Lighting Systems

- Power Regulation in Three-Phase Motors